From Start to Finish, Fully Traceable & Smartly Controlled

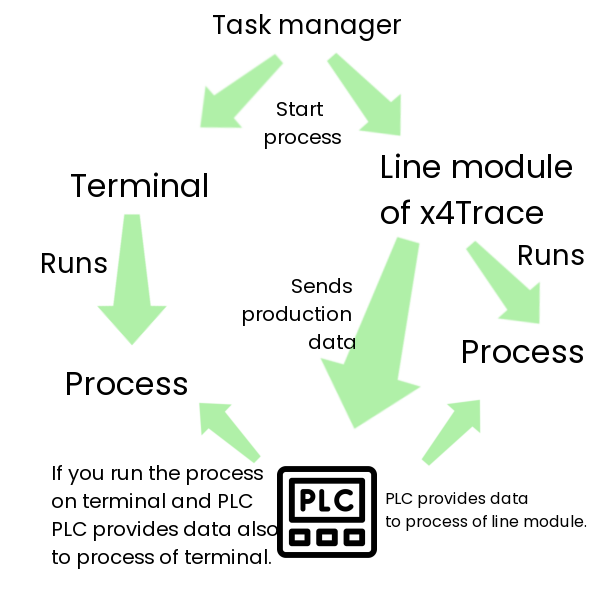

Every production run in x4Trace is launched either from an operator terminal or a connected PLC and is instantly assigned a unique Production Process ID, ensuring every batch, operation, and touchpoint becomes fully traceable across your shop floor.

A new production begins with a unique ID shared across terminals, PLCs, or the x4Trace server—no matter where it’s started—guaranteeing total traceability from launch to completion.

Under each production process, vital data—including passed parts, trace events, involved operators, timestamps, and activity logs—are automatically collected and associated with the specific order and operation.

Whether the process starts at a terminal or a PLC, x4Trace ensures all endpoints—human or machine—are in sync. Terminals, PLCs, and the server collaborate to collect and log production data precisely.

Instant Production Instantiation & Tracking:

A new production begins with a unique ID shared across terminals, PLCs, or the x4Trace server—no matter where it’s started—guaranteeing total traceability from launch to completion.

Rich Data Capture at Every Step:

Under each production process, vital data—including passed parts, trace events, involved operators, timestamps, and activity logs—are automatically collected and associated with the specific order and operation.

Seamless PLC Integration:

Whether the process starts at a terminal or a PLC, x4Trace ensures all endpoints—human or machine—are in sync. Terminals, PLCs, and the server collaborate to collect and log production data precisely.

Full Traceability:

Every production is uniquely tracked through IDs, linking operations, orders, and data at every stage.

Smart Integration:

Smoothly orchestrates terminals, PLCs, and back-end systems for unified execution and real-time data capture.

Data-Rich Analytics:

Supports detailed insights—operator involvement, part movement, process duration—for stronger quality control and reporting.

Operational Flexibility:

Launch from multiple control points—operator terminals or PLCs—with fallback options handled transparently by the x4Trace server.

The Bottom Line

With x4Trace Production, you don’t just manage manufacturing—you orchestrate and monitor it with precision, transparency, and intelligence. Each production run becomes a well-documented, fully traceable process, every part tracked, every operator visible, every outcome quantifiable. This isn’t just software; it’s your production system’s backbone.Connected articles: