Seamless Integration Between x4Trace and Your ERP System

The ERP Communication feature in x4Trace facilitates smooth data exchange between your manufacturing operations and ERP system, ensuring real-time synchronization and accurate information flow across your organization.

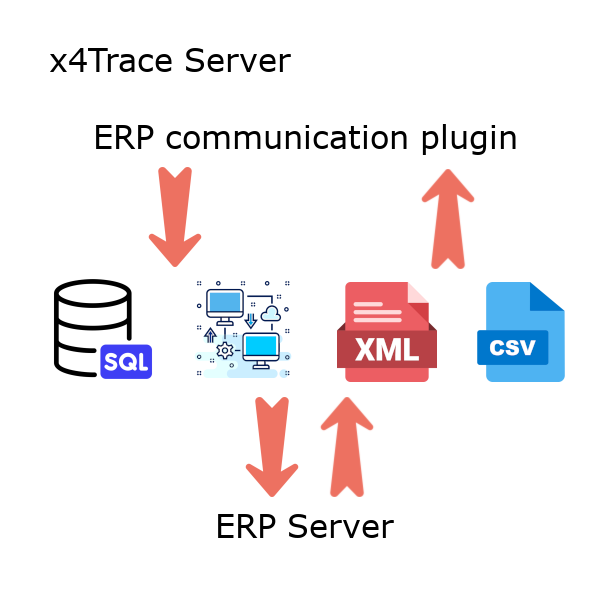

Built-in Server Plugin:

x4Trace includes a built-in server plugin for ERP communication, supporting data exchange via SQL Server or XLS files. This plugin serves as a foundation for creating a customized interface tailored to your specific ERP system.

Flexible Data Exchange:

Data can flow in both directions: retrieve production data from the ERP system to x4Trace, and upload production results or reports from x4Trace back to the ERP system. This bidirectional communication ensures that both systems are aligned and up-to-date.

Customizable Integration:

While the built-in plugin provides basic functionality, you have the flexibility to develop a custom server plugin that reads communication files or connects directly to the ERP database. This customization allows for a seamless integration that meets your specific requirements.

Data Summarization:

x4Trace stores detailed production data at all times. When communicating with the ERP system, you can choose to insert summarized production data, reducing the amount of data transferred and focusing on key metrics.Open Development Environment:

x4Trace offers an open development environment, enabling you to develop and extend the ERP communication interface as needed. Access to the source code of the sample ERP communication plugin is available, providing a starting point for your integration efforts.Why Choose x4Trace’s ERP Communication Feature?

Implementing the ERP Communication feature in x4Trace ensures seamless integration between your manufacturing operations and ERP system. The built-in server plugin provides a solid foundation for data exchange, while the customizable integration options allow for a tailored solution that fits your specific needs. Bidirectional data flow ensures that both systems are synchronized, enhancing operational efficiency and decision-making.