Visualize, Control, and Optimize Your Production Processes

The Flow feature in x4Trace offers a dynamic, flowchart-based approach to designing and managing your production processes. This intuitive tool allows you to map out each step of your manufacturing workflow, from material input to final product output, ensuring a seamless and efficient production cycle.

Visual Workflow Mapping:

Easily design your production process using a drag-and-drop interface. Each operation is represented as a node, connected by arrows that define the sequence and dependencies. This visual representation aids in understanding complex workflows and identifying potential bottlenecks.

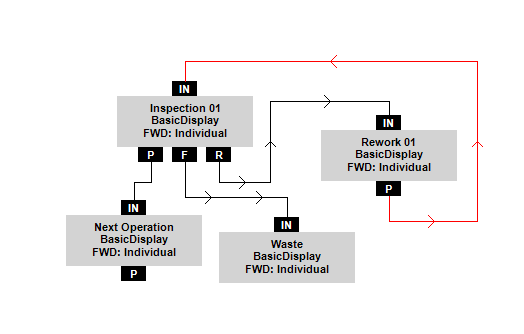

Multi-Outcome Operations:

Operations within the flow can have multiple outcomes, such as pass, fail, or rework. Based on real-time data from operators, PLCs, or inspection machines, parts are directed accordingly, ensuring quality control and minimizing defects.

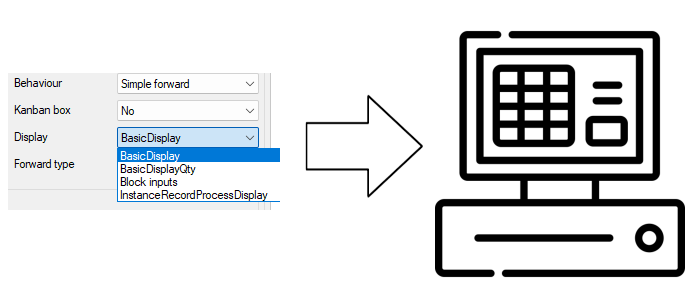

Customizable Terminal Displays:

Each operation can have its own terminal interface, displaying relevant information and instructions to operators. These displays are customizable to fit specific needs, enhancing user experience and reducing training time.

Seamless Integration with Devices:

Connect operations to various devices on the production line, including PLCs and other equipment. x4Trace facilitates communication between these devices and the MES, enabling real-time data exchange and process synchronization.

Comprehensive Data Collection:

Collect detailed data at each operation, including part information, operator inputs, and machine statuses. This data is invaluable for traceability, quality assurance, and performance analysis.

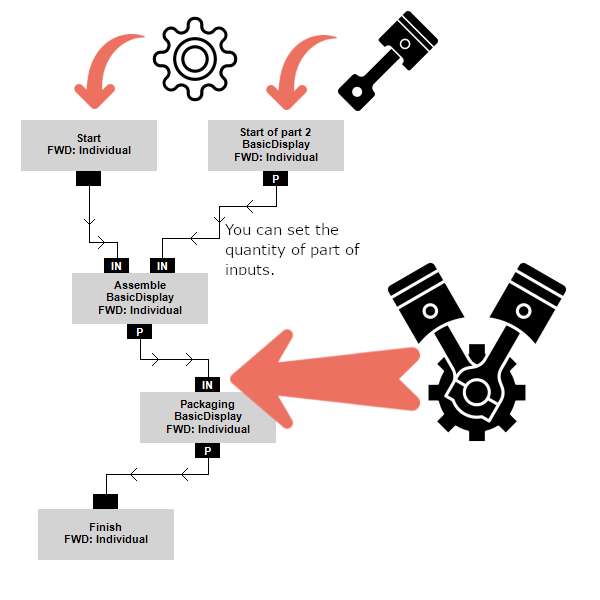

Assembly Management:

Define and manage components within the production order. Specify quantities or unique IDs for each part, and track their usage throughout the production process, ensuring accurate inventory management and assembly accuracy.Document Integration:

Attach relevant documents, such as PDFs, to specific operations. These documents can be accessed directly from the terminal interface, providing operators with immediate access to manuals, work instructions, or quality standards.

Why Choose x4Trace’s Flow Feature?

By implementing the Flow feature, manufacturers can achieve greater control over their production processes. The visual workflow mapping simplifies process design and modification, while real-time data collection enhances decision-making and process optimization. Integration with various devices and systems ensures a cohesive and efficient production environment. Ultimately, x4Trace’s Flow feature contributes to improved product quality, reduced downtime, and increased overall efficiency.Connected articles: