Smart. Visual. Effortless.

At a Glance: x4Trace revolutionizes manufacturing execution by turning your production workflow into an interactive, visible flow—designed visually, executed automatically, and fully traceable.

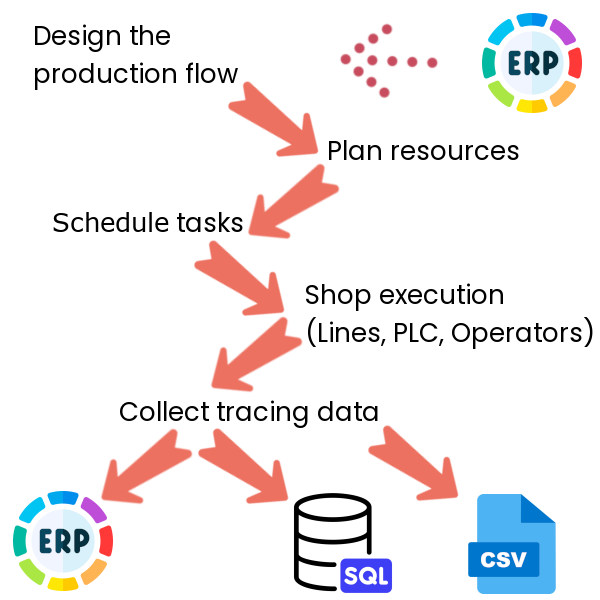

Step-by-Step Workflow: From Flow Design to Insight

1. Visual Workflow Design

Create your entire production process like a flowchart. Define each operation, route parts dynamically, and include branching logic for quality checks or rework. This visual-first approach ensures clarity and eliminates the guesswork.2. Execution—Fully Automated or Operator-Driven

Once you’ve designed the flow, x4Trace brings it to life:

- Sends real-time commands to PLCs, operator terminals, and all shop devices.

- Guides parts through each station, handles routing logic, and adapts instantly.

- Supports both manual and fully automated execution modes.

3. Live Data Collection & Traceability

x4Trace captures vital production data at every step—from batch IDs and operator inputs to sensor outputs and timestamps—creating a rich, searchable trace record.4. Seamless ERP & Reporting Integration

All collected data can flow directly into your ERP—or vice versa—ensuring real-time synchronization and insight. Built-in reporting tools enable you to generate actionable analytics or export results effortlessly.

Your x4Trace Workflow in Two Sentences

1. Visualize workflows as flowcharts—design how parts move, branch, rework, and complete.

2. Let x4Trace execute the flow, collect trace data, integrate with ERP, and deliver actionable reports.