Streamline Your Workflow with Smart Tracking

The Kanban feature in x4Trace enables seamless tracking of parts through dynamic Kanban box registration. As a part completes an operation, it’s automatically moved from a source to a destination box—no extra steps required. Each product retains its Kanban box ID throughout the process, giving you full visibility and control.

Automated Box Tracking:

When a part completes an operation, it’s instantly re-registered in a new Kanban box, and automatically removed from its previous one. Registration is effortless and error-free.

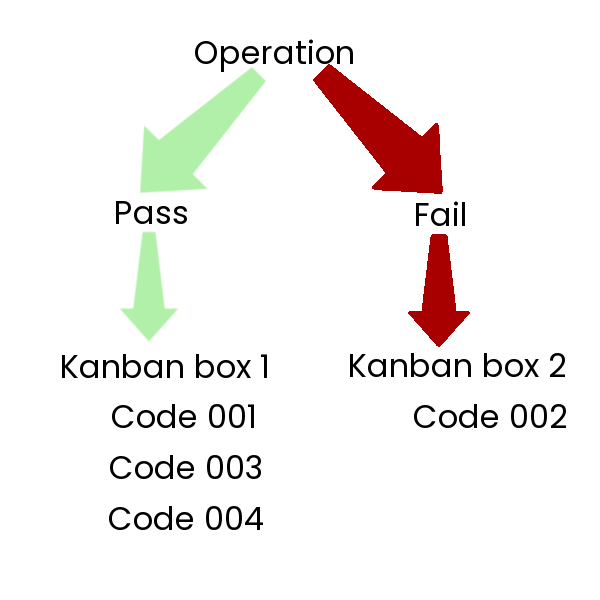

Result-Based Sorting:

Parts are automatically routed based on outcomes. For example: “Pass” results go to Kanban box 1, while “Fail (Code 002)” parts are sent to Kanban box 2.

ID-Based Selection:

Operators simply select the Kanban box ID during processing, ensuring accurate registration and traceability with minimal effort.

Location-Aware Storage:

Each Kanban box is linked to a storage location, helping you maintain an organized, efficient layout in your production area.

Why Choose x4Trace’s Kanban Feature?

With x4Trace’s Kanban system, you get intuitive, automated part tracking that adapts to your production logic—whether routing by outcome or location. This elevates traceability, enhances workflow clarity, and reduces manual handling—so your operations stay lean, responsive, and error-free.